LED Tube Retrofits

LED Tube Retrofits: The Benefits and Types

The Benefits of LED Tube Retrofits

As the technology of LEDs and their drivers have improved, lighting manufacturers have developed LED bulbs to replace older and less-efficient lighting types, known as LED retrofits. These days, LED retrofits can be found in all types of applications, from day-to-day residential and commercial lighting, to high-intensity outdoor and industrial lighting. The latter being where the endurance and consistent brightness of LEDs are crucial for safety. In nearly every setting, LED retrofits can be seen outperforming their counterparts in key aspects such as improved light-up time and longer lifespans.

LED retrofits have been developed to replace a multitude of conventional bulb types, including household incandescent bulbs, high-intensity discharge lamps, and compact fluorescent lamps. A popular type of LED retrofit is fluorescent tube replacements. The advancement of lighting technology has made conventional fluorescent lamps as energy efficient as ever. Still, today’s most cost-effective lighting solution is to replace fluorescent and incandescent lighting with LEDs. These replacements are far more energy efficient than fluorescent tube lamps because LEDs have a much better watt to lumen ratio. This means that less energy overall is required to reach the desired level of light. Meanwhile, fluorescent tubes use increasingly more energy to reach that same level of light while simultaneously wasting much of that energy as unwanted heat. The improved watt to lumen ratio of LEDs ultimately leads to less energy consumption and thus lower electrical bills; both of which are particularly important in today’s energy conscious world.

In addition to this, LED tube retrofits are much more resilient and do not contain the hazardous materials found within fluorescent tube lamps. The metal halide gas inside the lamp contains toxic metals such as mercury, so they must be disposed of carefully. Moreover, fluorescent tubes must be made of glass and can easily break during shipping or even while handling. LED tubes, however, can be safely recycled and are typically made of either durable plastic or shatterproof glass. They also offer a greater range of color temperature beyond the limits of conventional fluorescent lamps. Dimming is easier to implement on LED tubes too, especially when paired with a user-programmable LED driver. The list just goes on.

The Types of LED Tube Retrofits

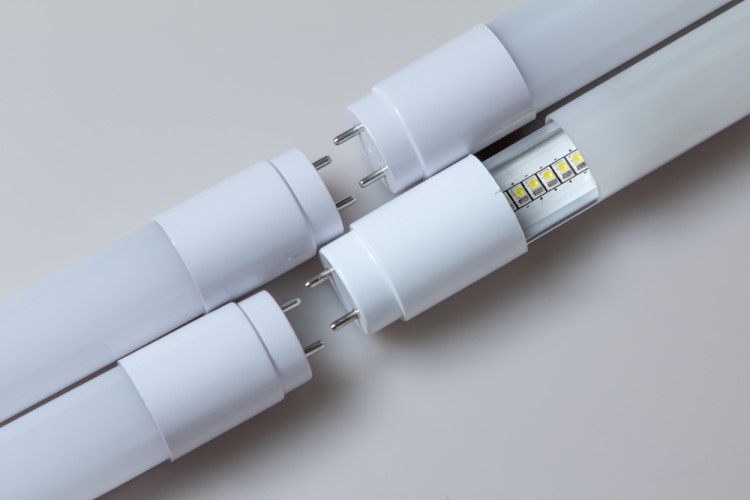

So, how do you replace old fluorescent tube lamps with new LED tube retrofits? Luckily, choosing the correct type of tube is fairly straightforward. To simplify the installation process, LED tubes share the same measurements to conventional fluorescent tubes. For example, our catalog of LED tubes includes the T5, T8, and T12 sizes. This number measures the diameter of the tube in 1/8 of an inch. T5 tubes have a diameter of 0.625 inches, or 5/8 inches. T8 tubes are 1 inch, or 8/8 inches in diameter and T12 are 1.5 inches, or 12/8 inches in diameter. Manufacturers have also taken note of the switch to LEDs, so it is likely that you can find LED tube equivalents for your favorite fluorescent brands.

The primary concern when choosing a LED tube retrofit is choosing the type of tube that best fits your application. There are four types of LED tube retrofits, Type-A, Type-B, Type-A+B, and Type-C. We will break down the usage of each type and then compare the advantages and disadvantages of each. This article should, hopefully, give you a better understanding of which retrofit type will work best as your fluorescent tube replacement.

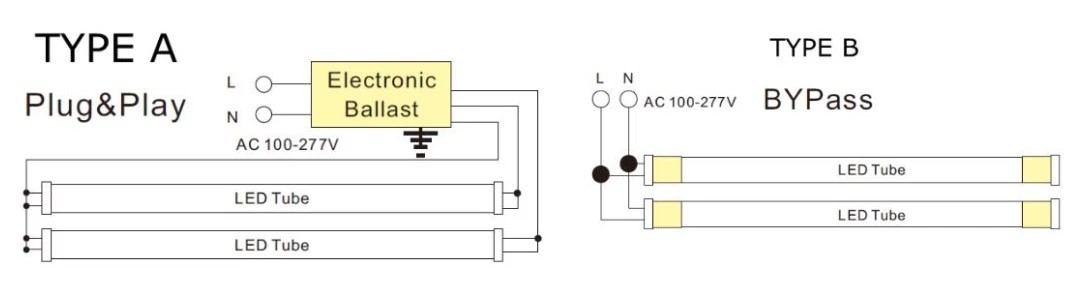

Type-A: Known as “Plug-n-Play” retrofits, Type-A has the fastest and easiest installation process of all the types. This type uses the existing electronic fluorescent ballasts and does not require any electrical modification. However, they cannot be used with magnetic fluorescent ballasts. Type-A retrofits are best suited for applications where fast and simple installation is desired.

Compatibility is the biggest hurdle when installing Type-A retrofits because they can only be used with electronic ballasts that are compatible with the retrofit. For a full list of compatible ballasts, be sure to check the LED manufacturer’s Ballast Compatibility List. Many popular lighting manufacturers carry “Plug-n-Play '' LED retrofits such as, GE Lighting, Keystone, Satco, and Philips. While Type-A retrofits are the easiest to install, it is recommended to replace the fluorescent ballast if it is more than a few years old. An older ballast has a higher chance of failing, leading to more maintenance required down the road. Additionally, the use of existing fluorescent ballast allows for very limited dimming control, but does offer better options than the Type-B retrofits.

Type-B: Known as “Ballast Bypass” retrofits, Type-B tubes are equipped with a built-in LED driver. This allows them to completely skip the fluorescent ballast and is powered directly by line voltage. As this type does not require a connection to an external fluorescent ballast or LED driver, the ballast compatibility and failure issues of the Type-A retrofits are eliminated. Both Type-A and Type-B are the most popular retrofit options and many of the manufacturers of Type-A tubes also offer Type-B equivalents (e.g., Commercial LED, Satco, Keystone, and Philips). While Type-B retrofits are more complicated to install, they tend to lead to less headaches in the long term.

Since the Type-B retrofits connect directly with input line voltage, it requires a certified electrician to remove the existing fluorescent ballast and re-wire the fixture. Failure to follow the manufacturer’s installation instructions can lead to serious safety risks such as shock or fire hazards, as well as the complete failure of the fixture. Type-B retrofits have very little dimming options in comparison to the other types and are known to

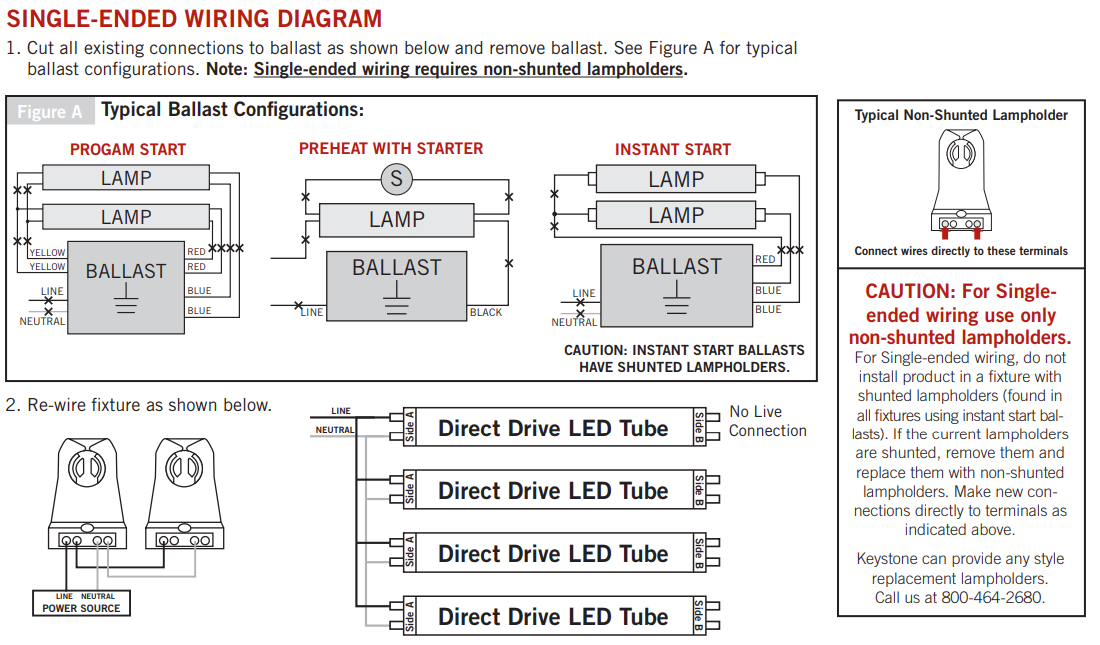

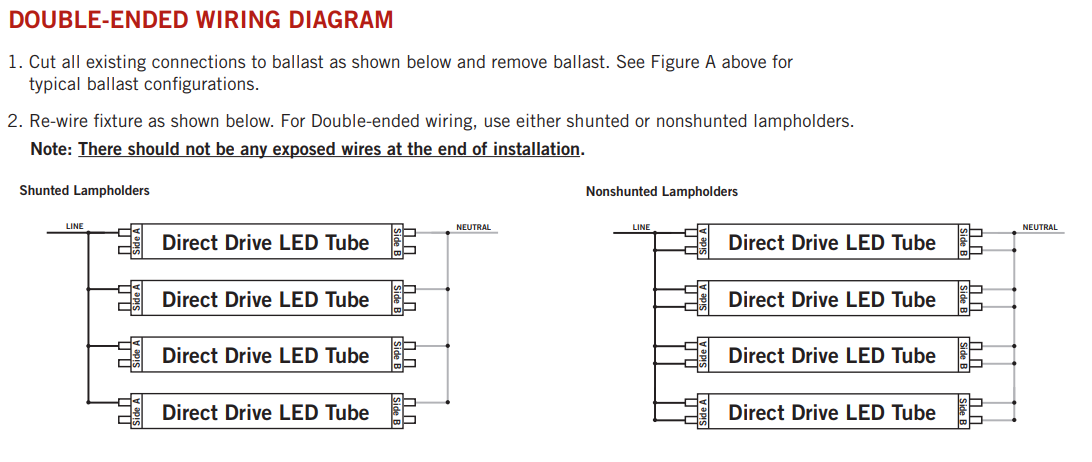

There are two types of Type-B retrofits, single-ended and double-ended. As their names suggest, single-ended tubes are only connected on one side of the fixture, whereas double-ended tubes use connections on both ends of the fixture. Single-ended tubes boast reduced maintenance needs, but the safety risks that these tubes pose tend to ultimately outweigh their benefits. Single-ended tubes have a greater risk of shock and fire hazards, as well as higher rates of failure. Additionally, nonshunted sockets are needed for the safe installation of single-ended tubes. Due to these concerns, manufacturers have begun to phase out their single-ended tubes in favor of double-ended tubes.

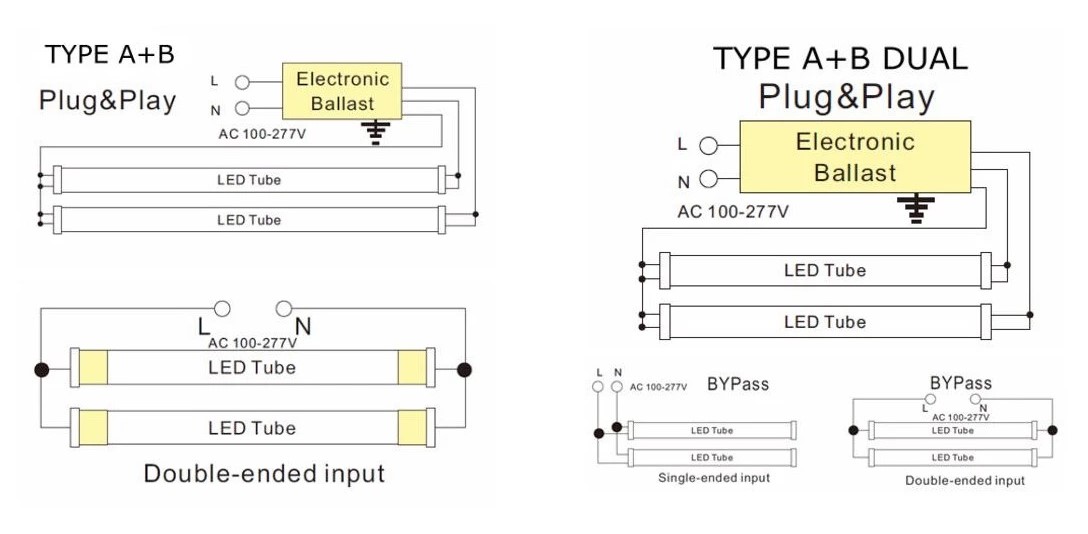

Type-A+B: Known as “Hybrid” retrofits, Type-A+B is a compromise between Type-A and Type-B. Type-A+B retrofits can work both with or without an existing electronic fluorescent ballast. This type is the best option when it is unsure if the existing ballast is compatible with the LED tube. And unlike Type-A retrofits, this type will continue to operate if the ballast fails. Removing the constraints of ballast compatibility allows for greater choice in both LED and ballast manufacturers. Their increased flexibility and simplified installation process make these “hybrid” tubes the most versatile type of LED retrofit.

Type-C: Known as “Remote Driver” retrofits, this last type of LED retrofit replaces the existing fluorescent ballast with an external or “remote” LED driver. Just like the Type-B retrofits, Type-C does require an extensive rewiring of the former fluorescent system. However, this type’s use of a LED driver allows for the greatest operation of the LED lamp. The driver helps to most efficiently utilize the LEDs’ benefits such as increased lifespan, greater efficiency, and with the least issues with ballast compatibility. This type is best used in applications where long lifespans and energy efficiency are the primary concerns. Type-C retrofits are the newest type and its biggest manufacturer, for the time being, is GE Lighting. Type-C retrofits also offer the best dimming control options when paired with user programmable LED drivers. Moreover, a single LED driver can be set up to power several arrays of Type-C retrofits. For more information on LED drivers, check out our blog post on the subject here.

If you have any further questions on which type of LED retrofit is the best for you, please don’t hesitate to contact us at 888-307-3700. We have qualified lighting specialists that will make sure that you get the product that best suits your needs.

-

Satco S28694 LED T5 Bulb - 12T5/LED/24-840/BP/HO/SE-DESpecial Price $13.95 Regular Price $18.44

Satco S28694 LED T5 Bulb - 12T5/LED/24-840/BP/HO/SE-DESpecial Price $13.95 Regular Price $18.44 -

Satco S28693 LED T5 Bulb - 12T5/LED/24-835/BP/HO/SE-DESpecial Price $13.25 Regular Price $18.44

Satco S28693 LED T5 Bulb - 12T5/LED/24-835/BP/HO/SE-DESpecial Price $13.25 Regular Price $18.44 -

Philips 590224 9.5T8/MAS/48-835/MF17/G/DIM UE 25/1 T8 Type-BSpecial Price $17.73 Regular Price $19.50

Philips 590224 9.5T8/MAS/48-835/MF17/G/DIM UE 25/1 T8 Type-BSpecial Price $17.73 Regular Price $19.50 -

Philips 589804 - 43T8/COR/96-5CCT/MF52LS/G/FA8-R17D 10/1 8' Type B T8 LED BulbSpecial Price $36.95 Regular Price $48.28

Philips 589804 - 43T8/COR/96-5CCT/MF52LS/G/FA8-R17D 10/1 8' Type B T8 LED BulbSpecial Price $36.95 Regular Price $48.28 -

Philips 588632 10.5T8/COR/36-5CCT/FF15/G/DIM 25/1 T8Special Price $17.38 Regular Price $19.12

Philips 588632 10.5T8/COR/36-5CCT/FF15/G/DIM 25/1 T8Special Price $17.38 Regular Price $19.12 -

Philips 588624 7.5T8/COR/24-5CCT/FF11/G/DIM 25/1 T8Special Price $16.91 Regular Price $18.60

Philips 588624 7.5T8/COR/24-5CCT/FF11/G/DIM 25/1 T8Special Price $16.91 Regular Price $18.60 -

Philips 588616 9.5T8/MAS/48-850/MF18/G/DIM UE 25/1 T8 Type-BSpecial Price $17.73 Regular Price $19.50

Philips 588616 9.5T8/MAS/48-850/MF18/G/DIM UE 25/1 T8 Type-BSpecial Price $17.73 Regular Price $19.50 -

Philips 588608 9.5T8/MAS/48-840/MF18/G/DIM UE 25/1 T8 Type-BSpecial Price $17.73 Regular Price $19.50

Philips 588608 9.5T8/MAS/48-840/MF18/G/DIM UE 25/1 T8 Type-BSpecial Price $17.73 Regular Price $19.50 -

Philips 583996 10T8/COR/48-850/DF16/G/DIM UL-C 25/1 T8 Type-CSpecial Price $9.22 Regular Price $10.14

Philips 583996 10T8/COR/48-850/DF16/G/DIM UL-C 25/1 T8 Type-CSpecial Price $9.22 Regular Price $10.14 -

Philips 583988 10T8/COR/48-840/DF16/G/DIM UL-C 25/1 T8 Type-CSpecial Price $9.22 Regular Price $10.14

Philips 583988 10T8/COR/48-840/DF16/G/DIM UL-C 25/1 T8 Type-CSpecial Price $9.22 Regular Price $10.14 -

Philips 583970 14T5/COR/46-850/DF21/G/DIM UL-C 25/1 T5 Type-CSpecial Price $11.25 Regular Price $12.38

Philips 583970 14T5/COR/46-850/DF21/G/DIM UL-C 25/1 T5 Type-CSpecial Price $11.25 Regular Price $12.38 -

Philips 583962 14T5/COR/46-840/DF21/G/DIM UL-C 25/1 T5 Type-CSpecial Price $11.25 Regular Price $12.38

Philips 583962 14T5/COR/46-840/DF21/G/DIM UL-C 25/1 T5 Type-CSpecial Price $11.25 Regular Price $12.38 -

Philips 580274 11.5T8/COR/48-840/IF21/G/DIM 25/1 T8 Type-ASpecial Price $15.30 Regular Price $19.74

Philips 580274 11.5T8/COR/48-840/IF21/G/DIM 25/1 T8 Type-ASpecial Price $15.30 Regular Price $19.74 -

Philips 580266 11.5T8/COR/48-835/IF20/G/DIM 25/1 T8 Type-ASpecial Price $15.30 Regular Price $19.74

Philips 580266 11.5T8/COR/48-835/IF20/G/DIM 25/1 T8 Type-ASpecial Price $15.30 Regular Price $19.74 -

Philips 579474 14.5T8/MAS/48-830/MF20/P/DIM 25/1 T8 Type-B - LIMITED STOCK Remaining!!!Special Price $13.85 Regular Price $18.12

Philips 579474 14.5T8/MAS/48-830/MF20/P/DIM 25/1 T8 Type-B - LIMITED STOCK Remaining!!!Special Price $13.85 Regular Price $18.12 -

Philips 579466 10.5T8/MAS/48-850/MF16/P/DIM 25/1 T8 Type-BSpecial Price $13.85 Regular Price $16.14

Philips 579466 10.5T8/MAS/48-850/MF16/P/DIM 25/1 T8 Type-BSpecial Price $13.85 Regular Price $16.14 -

Philips 579458 10.5T8/MAS/48-840/MF16/P/DIM 25/1 T8 Type-BSpecial Price $13.85 Regular Price $16.14

Philips 579458 10.5T8/MAS/48-840/MF16/P/DIM 25/1 T8 Type-BSpecial Price $13.85 Regular Price $16.14 -

Philips 579441 10.5T8/MAS/48-835/MF15/P/DIM 25/1 T8 Type-BSpecial Price $13.85 Regular Price $16.14

Philips 579441 10.5T8/MAS/48-835/MF15/P/DIM 25/1 T8 Type-BSpecial Price $13.85 Regular Price $16.14 -

Philips 579391 12T8/COR/48-850/MF18/G/DIM 25/1 T8 Type-BSpecial Price $9.07 Regular Price $9.98

Philips 579391 12T8/COR/48-850/MF18/G/DIM 25/1 T8 Type-BSpecial Price $9.07 Regular Price $9.98 -

Philips 579342 12T8/COR/48-830/MF17/G/DIM 25/1 T8 Type-BSpecial Price $9.07 Regular Price $9.98

Philips 579342 12T8/COR/48-830/MF17/G/DIM 25/1 T8 Type-BSpecial Price $9.07 Regular Price $9.98 -

Philips 579334 9.9T8/COR/48-850/MF16/G/DIM 25/1 T8 Type-BSpecial Price $9.55 Regular Price $10.50

Philips 579334 9.9T8/COR/48-850/MF16/G/DIM 25/1 T8 Type-BSpecial Price $9.55 Regular Price $10.50 -

Philips 579318 9.9T8/COR/48-835/MF15/G/DIM 25/1 T8 Type-BSpecial Price $9.55 Regular Price $10.50

Philips 579318 9.9T8/COR/48-835/MF15/G/DIM 25/1 T8 Type-BSpecial Price $9.55 Regular Price $10.50 -

Philips 579060 16.5T8/CNG/48-850/MF21/G 25/1 T8 Type-BSpecial Price $7.00 Regular Price $7.70

Philips 579060 16.5T8/CNG/48-850/MF21/G 25/1 T8 Type-BSpecial Price $7.00 Regular Price $7.70 -

Philips 579052 16.5T8/CNG/48-840/MF21/G 25/1 T8 Type-BSpecial Price $7.00 Regular Price $7.70

Philips 579052 16.5T8/CNG/48-840/MF21/G 25/1 T8 Type-BSpecial Price $7.00 Regular Price $7.70 -

Philips 579045 16.5T8/CNG/48-835/MF20/G 25/1 T8 Type-BSpecial Price $7.00 Regular Price $7.70

Philips 579045 16.5T8/CNG/48-835/MF20/G 25/1 T8 Type-BSpecial Price $7.00 Regular Price $7.70 -

Philips 577791 14.5T8/CNG/48-865/MF18/G 25/1 T8 Type-BSpecial Price $7.04 Regular Price $7.74

Philips 577791 14.5T8/CNG/48-865/MF18/G 25/1 T8 Type-BSpecial Price $7.04 Regular Price $7.74 -

Philips 577783 14.5T8/CNG/48-850/MF18/G 25/1 T8 Type-BSpecial Price $7.04 Regular Price $7.74

Philips 577783 14.5T8/CNG/48-850/MF18/G 25/1 T8 Type-BSpecial Price $7.04 Regular Price $7.74 -

Philips 577767 14.5T8/CNG/48-835/MF17/G 25/1 T8 Type-BSpecial Price $7.04 Regular Price $7.74

Philips 577767 14.5T8/CNG/48-835/MF17/G 25/1 T8 Type-BSpecial Price $7.04 Regular Price $7.74 -

Philips 576744 24T5HO/COR/46-850/IF35/G/DIM 25/1 T5 Type-ASpecial Price $21.80 Regular Price $23.98

Philips 576744 24T5HO/COR/46-850/IF35/G/DIM 25/1 T5 Type-ASpecial Price $21.80 Regular Price $23.98 -

Philips 576736 24T5HO/COR/46-840/IF35/G/DIM 25/1 T5 Type-ASpecial Price $21.80 Regular Price $23.98

Philips 576736 24T5HO/COR/46-840/IF35/G/DIM 25/1 T5 Type-ASpecial Price $21.80 Regular Price $23.98 -

Philips 576710 24T5HO/COR/46-835/IF33/G/DIM 25/1 T5 Type-ASpecial Price $21.80 Regular Price $23.98

Philips 576710 24T5HO/COR/46-835/IF33/G/DIM 25/1 T5 Type-ASpecial Price $21.80 Regular Price $23.98 -

Philips 576256 25T5HO/COR/46-850/MF35/G 25/1 T5 Type-BSpecial Price $28.16 Regular Price $30.98

Philips 576256 25T5HO/COR/46-850/MF35/G 25/1 T5 Type-BSpecial Price $28.16 Regular Price $30.98 -

Philips 576231 25T5HO/COR/46-835/MF33/G 25/1 T5 Type-BSpecial Price $28.16 Regular Price $30.98

Philips 576231 25T5HO/COR/46-835/MF33/G 25/1 T5 Type-BSpecial Price $28.16 Regular Price $30.98